Commonly used hand-held cheese graters can be disected into two main parts: stainless steel grater blade and plastic handle.

The benefits of these materials is that they are the most commonly found materials for kitchen utensils and can last for a very long period of time fi taken care well.

The benefits of these materials is that they are the most commonly found materials for kitchen utensils and can last for a very long period of time fi taken care well.

While using the handheld cheese grater in 3 different positions we mapped out the areas of pain and pressure.

Since the grip of the grater is relatively the size of the hand the pressure on the hands and fingers while holding the grater is the maxim.

Also due to this small surface area of the grip all the pressure of holding and

maintaining the perfect angles is built up on the wrist.

Tightening the fingers around the grip also puts stress on the knuckles.

Since the grip of the grater is relatively the size of the hand the pressure on the hands and fingers while holding the grater is the maxim.

Also due to this small surface area of the grip all the pressure of holding and

maintaining the perfect angles is built up on the wrist.

Tightening the fingers around the grip also puts stress on the knuckles.

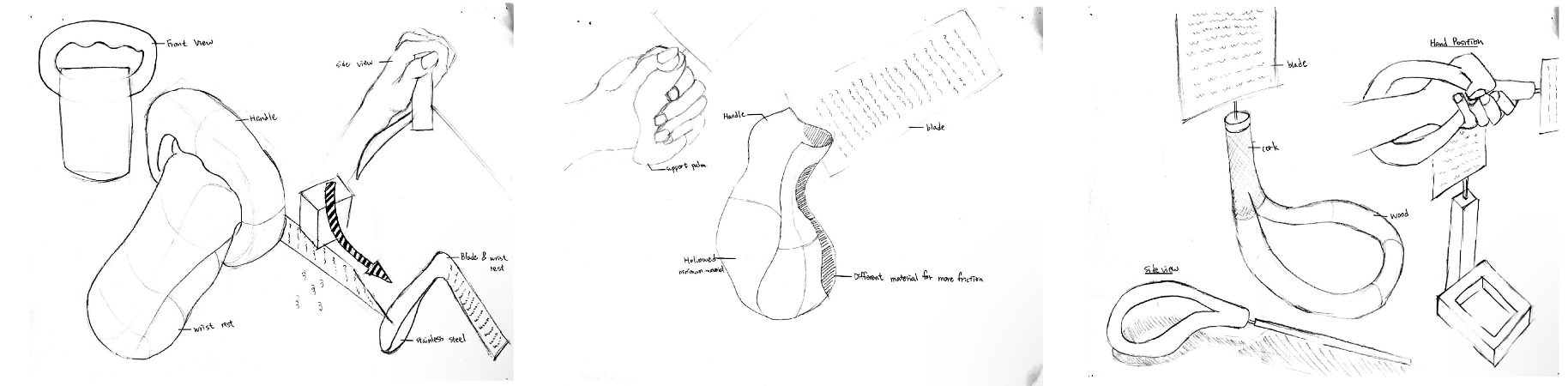

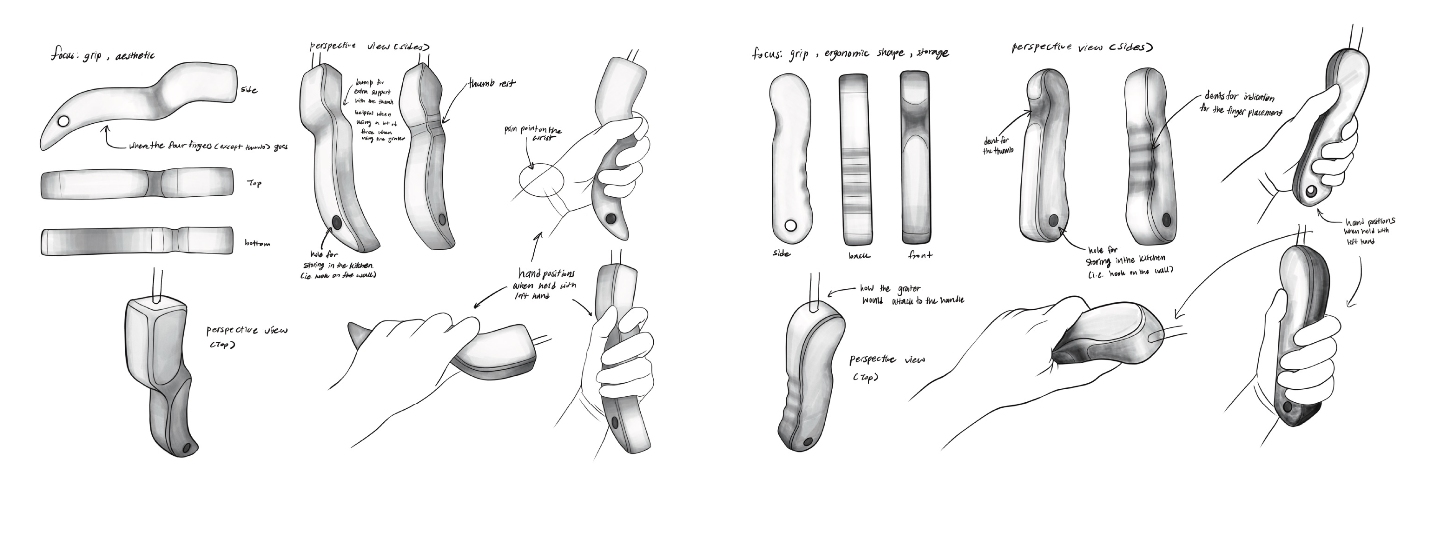

These are the four testing bucks that we made before making sketch models. We focused on different angles and hand positions to reduce the pain points.

After making the bucks, we had to test out each of them to figure out the effectiveness of those designs. We tried to hold it in many different positions as possible and evaluated the comfort level and effectiveness.

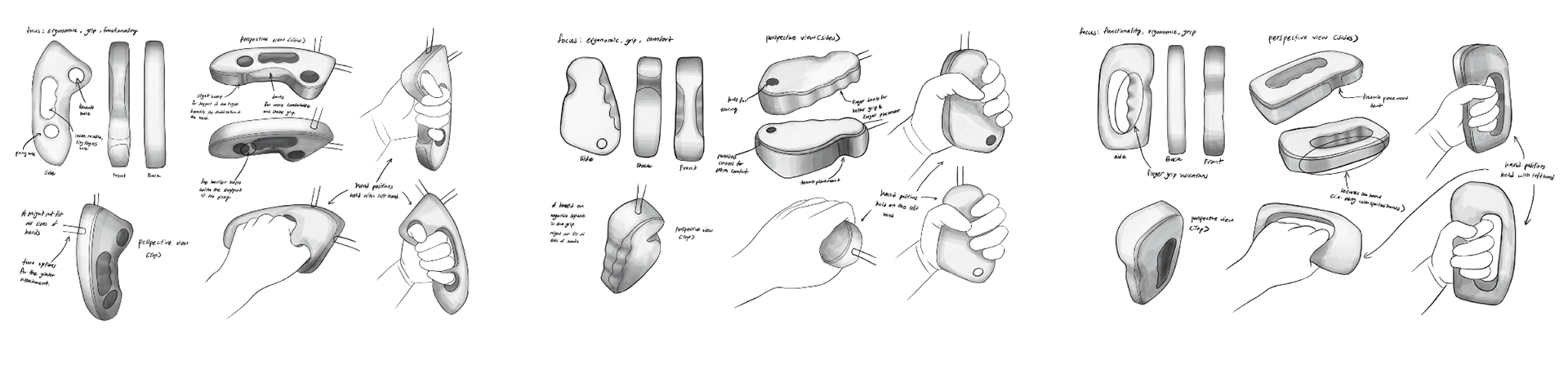

Doris-1

Doris-2

Sanya-1

Sanya-2

Sarah-1

Sarah-2

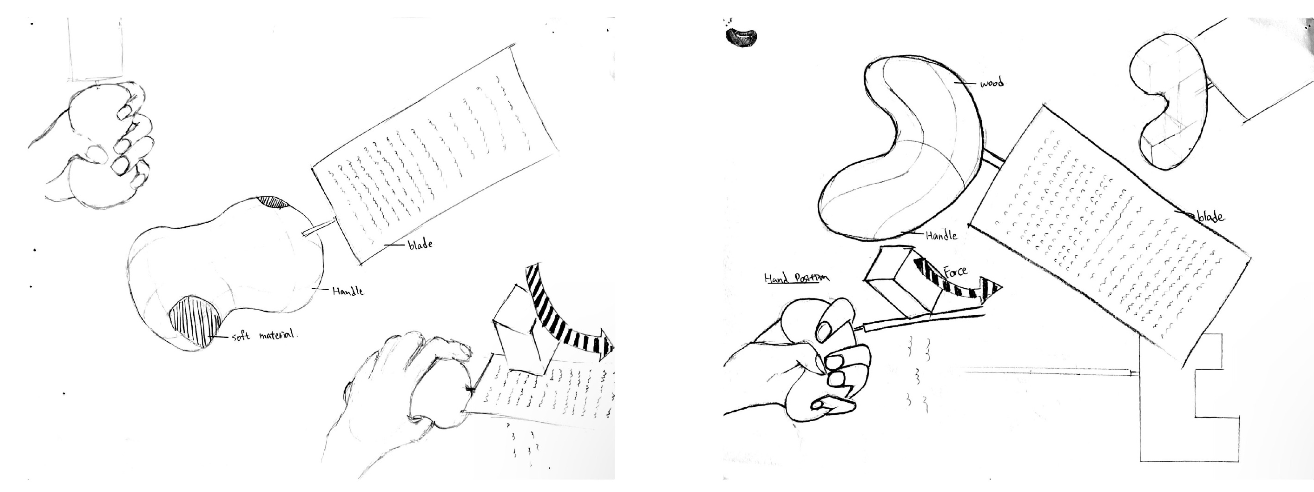

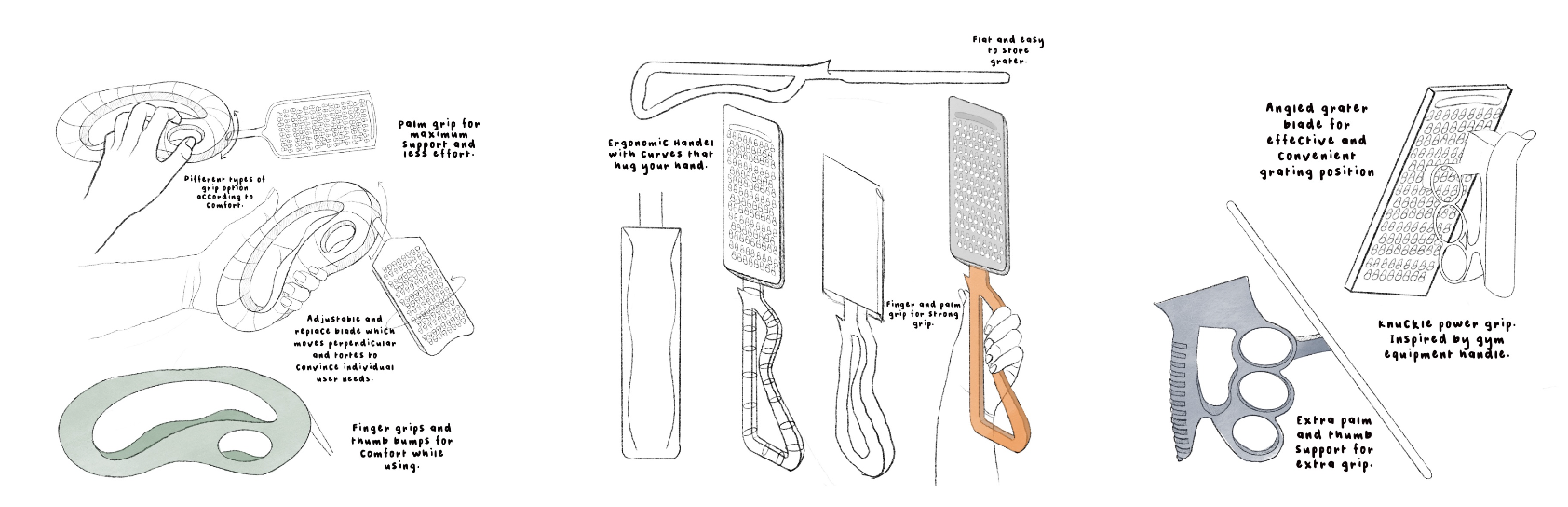

Exploratory drawing by Doris, Sanya, and Sarah

With directions toward sustainability, ergonomics, flexibility, and aesthetics in mind, we made 9 mockups in total. They were mostly revisions of either the testing buck or the sketch models. We used Poplar and Walnut for the mock-ups.

Clay testing

Poplar mock-ups

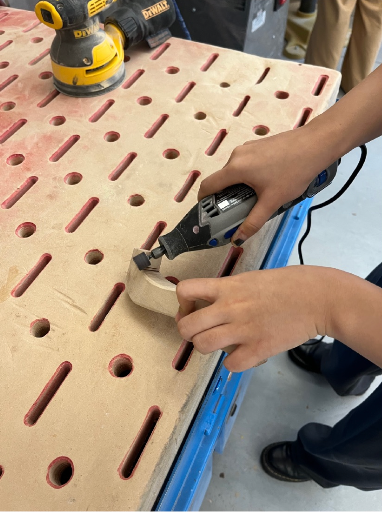

Band saw

Disc sander

Downdraft sander

Dremel

The biggest challenge was figuring out the joinery of the grater and the handle. These were the criteria we had to consider:

.1 No chemical adhesives

2. Easily Detachable mechanism

We wanted to make the mechanism

based on the Japanese saw but then the threaded insert would be hard to detach from the wood handle.

.1 No chemical adhesives

2. Easily Detachable mechanism

We wanted to make the mechanism

based on the Japanese saw but then the threaded insert would be hard to detach from the wood handle.

While trying to figure out the mechanism,

we tried to go with a very simple solution, which was creating a slit just big enough for the tang to fit in and inserting the bolt on the top.

we tried to go with a very simple solution, which was creating a slit just big enough for the tang to fit in and inserting the bolt on the top.

This was a huge success and it did not use chemical adhesive and was easily detachable.

Our groor stainless steel cheese grater is a sustainable and ergonomically designed hand-held grater. With an angle that is designed for a comfortable grip and more support, users experience less pain in their wrists while using it.

Made with maple, our handle is completely biodegradable. It is stained with coffee and finished with beeswax. Stainless steel grater and bolt can be recycled and reused.

Differentiated design of the handle focusing on the user and their comfort, groor provides the best cheese grating experience.

The dark stained wood brings an organic and natural feeling into the kitchen and has a timeless design.

Anyone can use it and detach it for recycling. The grater blade can be replaced into

different types of blades for different uses. Also, the users can adjust the face of the blades to achieve their most comfortable grip and position, making this tool versatile and comfortable.

Differentiated design of the handle focusing on the user and their comfort, groor provides the best cheese grating experience.

The dark stained wood brings an organic and natural feeling into the kitchen and has a timeless design.

Anyone can use it and detach it for recycling. The grater blade can be replaced into

different types of blades for different uses. Also, the users can adjust the face of the blades to achieve their most comfortable grip and position, making this tool versatile and comfortable.

Packaging is made only with recycled chipboard and everything is laser cut. The packaging does not use any chemical adhesives or colorings, making it eco-friendly.

Product benefits and recycling marks are on one side and the other side has information on how to detach the blade from the handle. An additional QR code is engraved for further video instructions on

step-by-step tutorial on the grater.

Product benefits and recycling marks are on one side and the other side has information on how to detach the blade from the handle. An additional QR code is engraved for further video instructions on

step-by-step tutorial on the grater.